Environment / Quality / Safety / Technology Enabled Business Solutions

Comments: No Comments

This is the second article in Kestrel’s Drones 101 series.

As we move into this important new phase of everyday use of drone technology in the workplace, some questions may arise:

- How many drones are there operating in commercial space?

- Where are they being used?

- How are they being used to help operations?

Commercial Drone Operation

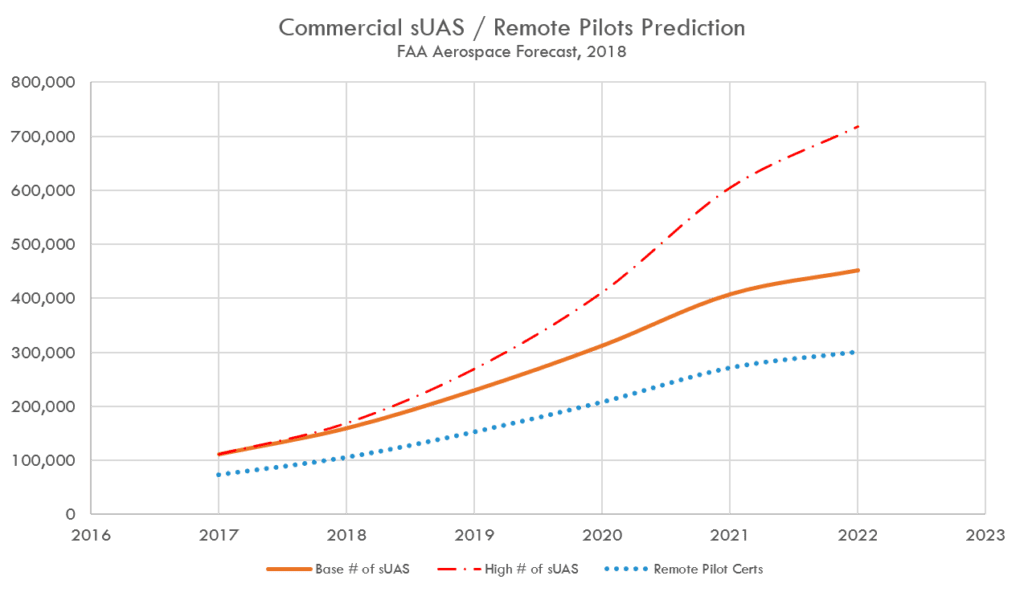

The chart below illustrates actual data from FAA’s aerospace forecast from this year. It highlights the phenomenal growth in drone use. The FAA projects that the commercial drone fleet is set to grow from over 110,000 in 2017 to over 450,000 by 2022 using its base, or most likely numbers. FAA’s high-end estimate predicts over 700,000 commercial drones in use by 2022. The number of remote pilots (indicated by the blue dotted line) is set to increase from 73,673 in 2017 to over 301,000 by 2022.

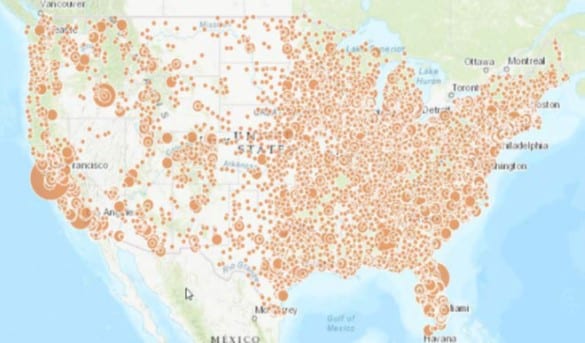

Further, the map below shows the distribution of registered commercial drones in the U.S. in 2017. The larger dots indicate a higher number of drones registered in that area. From this information you can see that commercial drones are popular and in use all over the country, not just in isolated pockets.

Further, the map below shows the distribution of registered commercial drones in the U.S. in 2017. The larger dots indicate a higher number of drones registered in that area. From this information you can see that commercial drones are popular and in use all over the country, not just in isolated pockets.

Typical Uses of Commercial sUAS

Typical Uses of Commercial sUAS

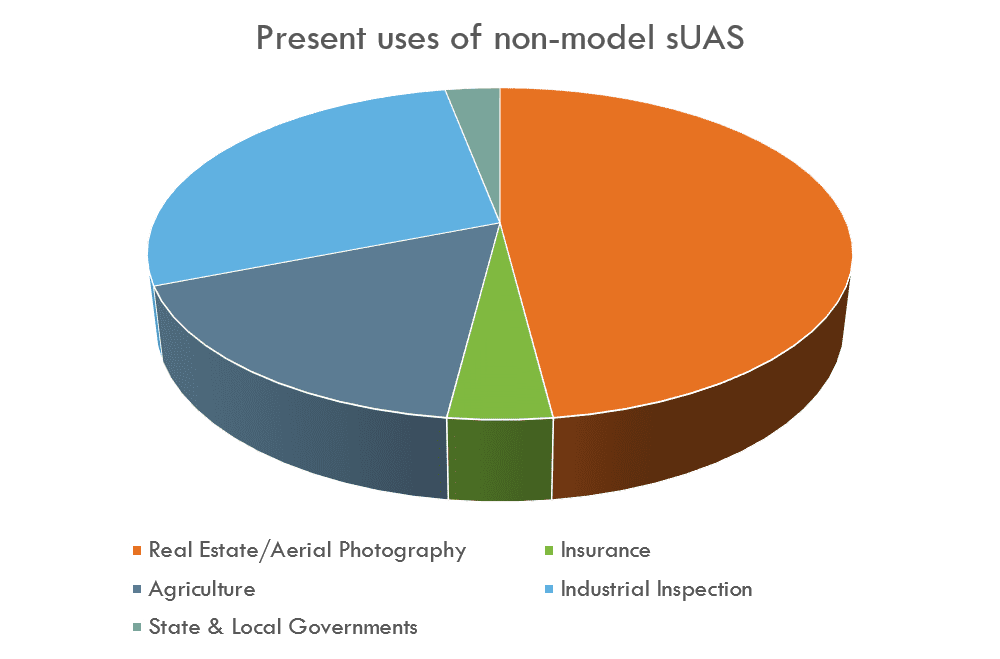

This pie chart from the FAA shows in a general sense how commercial drones are being used in the U.S. By far the most common use is aerial photography and mapping, followed by industrial inspection and agriculture. Insurance and state & local governments round out the chart. Construction is not represented separately on this chart, but it has been identified as the fastest growing industry segment in terms of drone use.

Why Drones?

Why Drones?

Using drones in commercial settings can clearly save time and money in many different ways, including the following:

- Outputs from drone applications can provide support, such as 3D modeling of existing facilities, evidence for insurance or legal claims, or cause-finding efforts for incident investigations.

- Drones can also be used to objectively monitor changes over time, such as erosion control, flood rise and water damage, or the rate of deterioration of fixed outdoor assets like tanks and towers.

- Sensors and software designed for drones offer quick, convenient means to measure stockpile volumes and inventories, evaluate flood plains, or quantify spills.

- Data captured can be used proactively to anticipate environmental risks, indicate preventive maintenance needs, or inform everyday decision-making.

- Drones can quickly and accurately determine stockpile volumes, which is very useful in the mining and aggregate industries.

- Finally, one of the most important uses of drones is to reduce employee exposure to hazardous conditions. These might include working at heights, confined spaces, or any situation where there is a risk of injury or death.

Drone Applications in Action

Let’s take a look at two examples of drones in action.

Application 1: Cause Finding.

Drones are being used across various industries to enhance cause-finding efforts. These tools are especially useful when hazardous materials or conditions are involved, and when the assets involved are on fire, at height, or pose a high safety risk to those involved.

One example of this is railroad derailment prevention. Standard derailment prevention operations involve derailment cause-finding efforts, such as interviewing those involved, walking the site and taking photos by hand and at eye-level. Derailment sites for large Class I railroads can be well over a mile long and can include spilled hazardous materials or active fires depending on the severity of the incident. Inspecting these sites can be time consuming, risky and, since these events are always unplanned, they can be disruptive to those involved.

Using drones, companies have been able to fly a derailment site in a fraction of the time it would have taken a person or persons to walk the entire site. With a LiDAR unit attached to the drone, companies scan the site and, using the data points generated during data collection efforts, recreate the accident scene to scale back at home base. This technology allows for more advanced analytics to be run on the incident. By recreating the accident scene using the data gathered by the drone and an appropriate software package, companies have been able to pinpoint the exact reasons that a train has derailed.

In one such instance, a company was able to determine that one of its trains was loaded in such a way that the push and pull being placed on the couplers was stressed to the point of breakage after the train went over and down a section of undulating territory at a certain speed. The company was able to analyze the degree of the undulation, the relative age of the coupler(s) involved, and the exact moment and location of the derailment. By digitally reconstructing the scene, they could see exactly which part of the train began to wobble, why it became unsteady and what caused the trajectory observed at the derailment site. With the application of UAS technology, the company was able to turn these detailed insights into multiple proactive and response mitigation actions.

Application 2: Industrial Inspection.

Drones are being used at processing and manufacturing plants to identify faults and aid in predicting required maintenance on equipment. In certain applications, specially designed drones are flown into hazardous and confined spaces instead of sending workers in.

One example of the latter is the periodic internal inspection of a large industrial boiler at a mine in Utah. Typically, this is accomplished by installing scaffolding down the middle of the boiler so that a team of technicians can climb down and observe specific features looking for cracking and signs of wear. What is normally a week-long process is now done in half a day with a confined space drone, and literally saves hundreds of thousands of dollars, because production is shut down for hours instead of days.

At another tank farm, UAS operators set waypoints to fly the same route periodically to check for irregularities and deterioration on the tanks, as well as evidence of releases from tanks and piping. This allows for proactive repairs and more efficient maintenance efforts. With a thermal imaging camera attached to the drone, the operator can perform a rough visual level check on the tanks to confirm that individual level sensors on the tanks are performing as expected, so that product inventories are accurate.

Enhancing Operations

There are many ways that drones can be used to enhance operations, regardless of industry. Drones offer a tool to access and assess physical conditions, minimize risks, and enhance employee efficiency during job tasks that are otherwise routine/time consuming, difficult to accomplish (i.e., have a high safety risk, exposure to hazardous materials that could result in injury or death), challenging to reach/excessively large (i.e., working at heights or in confined spaces), or time-sensitive.

When implemented appropriately, using drones often results in a solution that is:

- Faster – Significantly reduce manhours to complete work (e.g., inspections, audits, monitoring) without requiring plant shutdown.

- Safer — Eliminate the need for humans to complete high-risk activities (e.g., climbing towers, entering confined spaces, inspecting disaster zones).

- More accurate — Gather comprehensive and reliable data with less room for human error and less variability.

Learn more about Kestrel’s UAS Program Management services. Be sure to check out the entire Drones 101 series: